The second Mastercam X7 Technology Preview is now available for download to all Mastercam customers currently on Maintenance! Here’s your chance to test-drive the latest technology that the upcoming Mastercam X7 release has to offer. This is a fully functional pre-release download allowing you to use all of your current Mastercam licenses for a timed period on the X7 platform. Take the opportunity to see the latest developments and give important feedback directly to the development team working to bring you Mastercam X7. Here are some of the updates you’ll see in Mastercam X7, slated for release later this quarter:

- The new Tool Manager provides an easy way to create, organize, and share your tooling information throughout your enterprise.

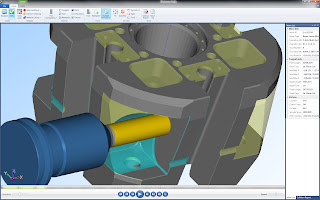

- Improved Backplot and Verify utilities offer a more efficient workflow, better analysis tools, and more comprehensive toolpath support.

- Dynamic and OptiRough toolpaths create more efficient tool motion, enhanced cut orders, and faster calculation times.

- Multi-threading support is extended to most 2D high speed toolpaths, resulting in faster toolpath processing.

- Oscillating motion for Curve and Swarf 5-axis toolpaths improves your tool life by varying the portion of the tool used to cut material.

- New Lathe Dynamic Roughing strategy for fast and efficient material removal.

- And much more...

.jpg)